Liquid Silica Gel (LSR) Injection Molding Machine

Basic Info

Model No.: TC-1200-GJ

Product Description

Liquid Silica Gel (LSR) Injection Molding Machine

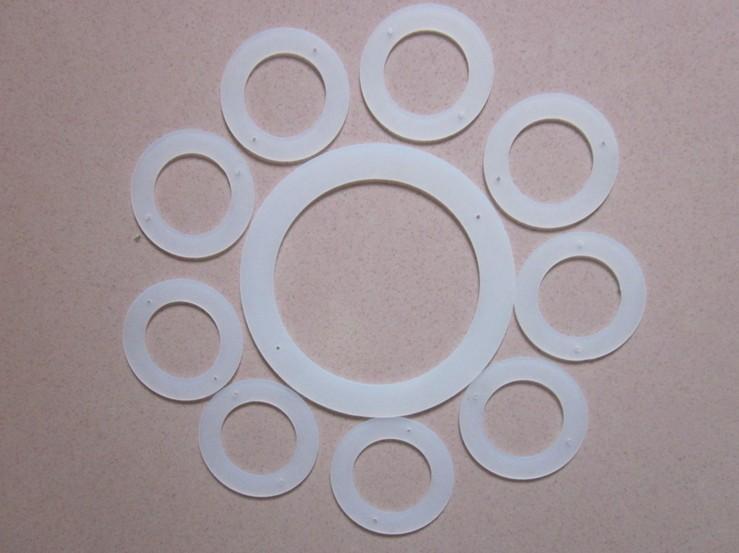

Liquid silica gel (LSR) injection moulding machine, which called LSR injection moulding machine. We can manufacture it combine with double slide board or rotary table series, and add the precision liquid silica gel special tube to work. The liquid silicone rubber injection molding machine of two series also can improve efficiency and enhance production capacity. So, the customers can select according the actaul demand. During the prodution, we use the well-know raw material of environmental and good quality to get Accurate Silica Gel , that is more suitable for sealing film, electronic digital products, waterproof, maternal and child products, medical products, etc. The most important is that customers can select servo liquid silicone rubber injection machine or high speed liquid silicone injection machine to achieve energy saving, precision and fast response.

Main Features

1. Combine with double slide board or rotary table, and add the precision liquid silica gel special tube to work.

2. Combined with well-know pump raw material supply equipment, which is environment friendly, precise and stable.

3. Accurate silica gel and the pigment is mixed with high viscosity silicone.

4. Optimised design of the insulation board to prevent heat loss.

5. Clients can select according the needs to do sing color silicone products or two-color silicone products.

Specifications

MODEL UNIT TC-1200-GJ

INJECTION UNIT Screw Diameter MM 40 45 Maximum Injection Pressure Kg/Cm2 2268 1838 Theoretical Shot Volume Cm3 201 254 Maximum Shot Weight(PS) G/oz 187/6.6 236/8.3 Injection Rate Cm3/sec 140 179 Screw Speed R/Min 0-200 Screw Stroke Mm 180 Nozzle Stroke mm 300 Number of Temperature Control _ 3

CLAMPING UNIT Clamping Force Ton 120 Opening Force Ton 10 Platen Size MM 1290x560 Slide Stroke MM / Rotary Table Diameter MM / Space Between Tie-Bar MM 780x380 Minimum Mold Thickness MM 280/380 Opening Stroke MM 280 Open Daylight MM 740/580 Max.Mold Weight Kg / Ejector Force Ton 4.1 Ejector Stroke MM 50

ELE.UNIT

Max.Hydraulic Pressure Kg/cm2 140 Pump Output l/min 63 Oil Tank Capacity L 400 Cooling Water Consumption I/h 800-1000 Electric Power Kw 15 Barrel Heating Power Kw 10.7 Total Wattage Kw 25.7

OTHERS Machine Dimension(Approx.) M 2.6x1.8x3.2 Machine Weight(Approx.) Kg 6000 Specifications are subject to change without prior notice.

Machine Picture

Machine Application

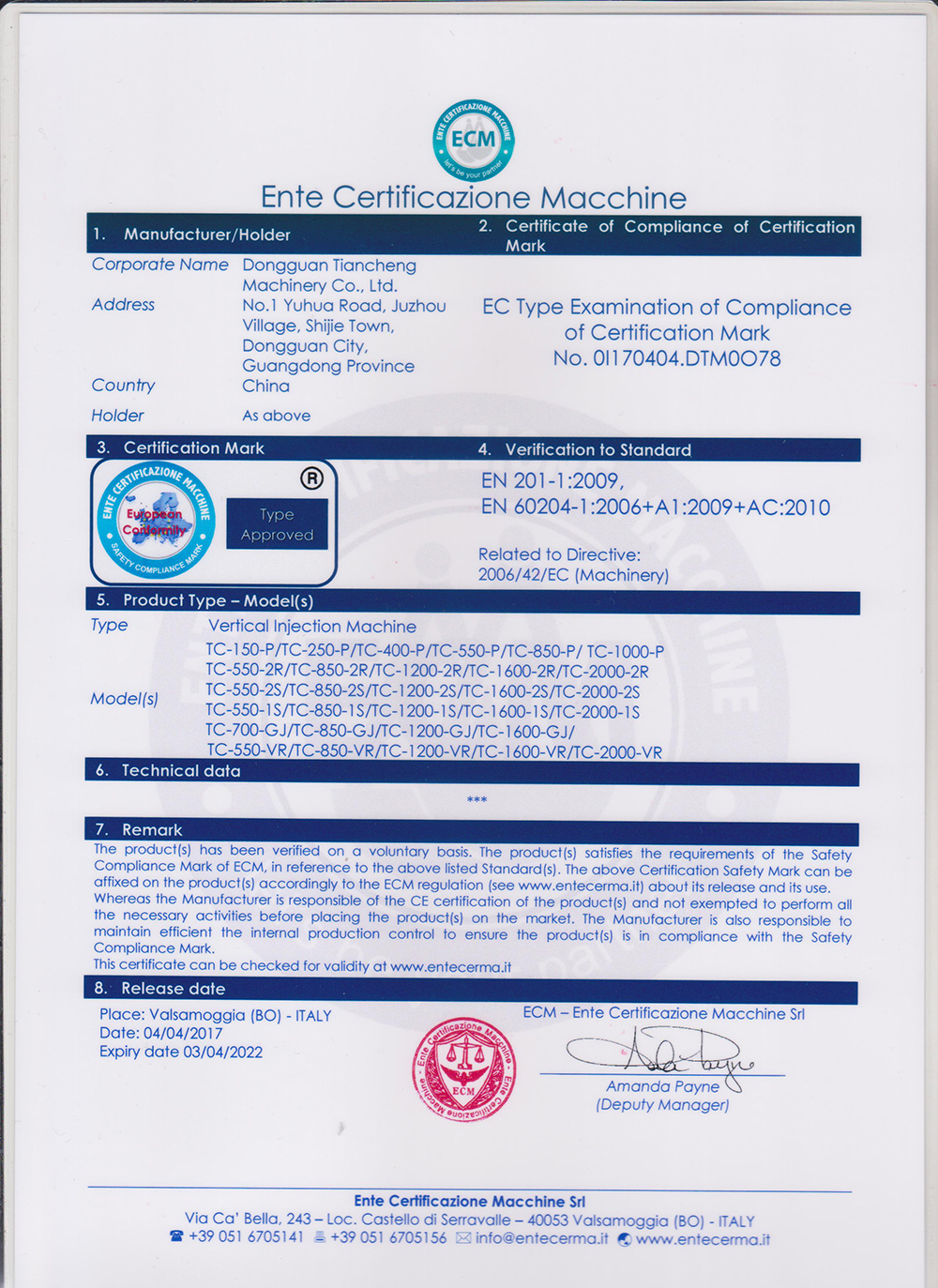

Certificate

Our Company

Dongguan Tiancheng Machinery Co.,Ltd. is a professional research and development, manufacturing and sales of vertical injection machines. Tianchen established in year 1999, locates in Shijie Town Dongguan City which is the word-famous manufacturing base. Our factory covers an area of more than 8000 square meters, owns advanced processing facilities and professional technical team, plus modern management system. Abundant overall ability ensure Tiancheng's advantages in technical ability, machine quality as well as competitive price.

Our Workshop

Delivery Time

1. Before shipping, we will check and test the machine carefully.

2. We will arrange manufacture after confirmation, we can delivery it usually after 35days.

3. According to the destination, we will compare several transportation companies and select the most suitable and economic one to provide service for us.

Our Service

Pre -Sales Service

1. Inquiry and consulting support.

2. Sample testing report.

3. View our Factory.

After-Sales Service

1. Training how to instal the machine by WeChat video.

2. Training how to use the machine by WeChat video.

FAQ

1) Are you manufacturer or trading company?

We are a manufactures for vertical injection molding machine and all machines are made by ourselves.

2) Can I be a agent in my market ?

We need talk details about agent agreement.

3) What's your website ?

www.gdtczs.com is offical one.

Product Categories : Plastic Injection Molding Machine Customer Applications > LSR Liquid Silicone Rubber Injection Molding Machine